FAQ

What is GRS 4.0 Global Recycled Standard?

A:

The Global Recycle Standard (GRS) was originally developed by Control Union Certifications (CU) in 2008 and ownership was passed to Textile Exchange January 1, 2011. This standard applies to the companies that wish to have a statement describing the content of recycled raw materials in their final products, and applies to any product that contains 20% or more recycled content.GRS refers to the definition of "Recycled Content" in ISO 14021, together with the explanation of the US Federal Trade Commission Green Guides, in order to comply with the most widely recognized and strict definition.

The GRS is based on the principle of tracking and tracing the verified products, and it also contains environmental and social responsibility related requirements applicable to all industries. With the development of the standard, it may choose to introduce the transaction certificate system, which can provide a better monitoring and control mechanism for the industrial supply chain, thereby ensuring the integrity of the verified product.

The GRS is designed for the applicants who join the GRS verification system. The applicant can be a company that trades and/or produces recycled products (finished or semi-finished products) and prepares to join the GRS verification system.

In addition to reviewing the production process, ingredient ratio and source of raw materials for the recycled products proposed by the applicant, GRS certification also needs to understand the quality control of its products. In addition, for the chemical management of recycled products, it is necessary to ensure the compliance with EU substances of high concern (REACH SVHC), ZDHC MRSL and GRS Hazard Codes. In addition to meeting the local laws and regulations, the environmental requirements must refer to the ZDHC Wastewater Guidelines for additional wastewater generated during the production. The final social responsibility section also refers to the local laws and regulations, and meets the requirements of GRS.

The scope of verification products is not limited to textiles. If the company outsources all or part of the production of finished products, the relevant production units must also comply with GRS standards.

(Information Source: cogp.greentrade.org.tw)

A:

To obtain GRS certification, the product must contain at least 20% of the raw materials composed of recycled fibers and be 100% pollution-free. Recycled fiber should also clearly indicate pre-consumer waste or post-consumer waste, as well as the proportion of pre-consumption and post-consumption both in recycled fiber. In addition to the regulations on raw materials, regulations on corporate social responsibility, pollution prevention & treatment in the production process, and chemical restrictions are all strengthened.GRS verifies 4 parts: recycled ingredients, social requirements, environmental, chemical requirements.

★Recycled Content:

- Products with a recycled content of 20% or more.

- Declared recycled materials should follow a complete and verified chain of custody from input to final product.

★Social Requirements:

- Workers employed by the companies involved in the production of GRS products are protected by strong social responsibility policies.

- GRS social requirements are based on the principles of the global social responsibility compliance program. In all cases, international labor standards, national and/or local legislation or the most stringent GRS requirements, the extent of its application should not violate applicable laws.

- Enterprises involved in the production of GRS products should have a high degree of environmental awareness.

- The environmental requirements of GRS apply to all businesses within the certification organization. In all cases, applicable to the most stringent national and/or local regulations or GRS requirements.

- The wastewater generated by the factory must be monitored/tested regularly.

- The chemicals used in the production of GRS products will not cause unnecessary harm to the environment or workers.

- GRS is only applicable to the use and management of chemicals in the manufacturing process of GRS products. This standard does not apply to the entire facility, but only to the production of GRS products. GRS does not deal with chemicals present in the final product because it cannot control any chemicals that may be present in recycled products used as initial inputs in the GRS production chain.

A:

In response to the strong demand for environmentally friendly textiles from brands and retailers, and to accelerate the sustainable development of the textile industry, the Control Union Certifications (CU) has launched the first Global Recycling Standard (GRS).With the continuous advancement of the low-carbon economy, the rational use of recycled resources has been concerned by more brand buyers and consumers. The reuse of materials can help reduce dependence on non-renewable resources, reduce waste discharge and environmental load caused by waste disposal, and contribute to the sustainable development of society.

A:

If company A wants to apply for GRS certification, its upstream suppliers should also have GRS certification. When GRS certification is conducted, their suppliers should provide GRS certificates and TC (Except for the factory at the source of the industrial chain, for example, a factory where the raw material is a bottle piece.)★Post-consumer recycled materials:Materials that are produced by households or commercial, industrial and institutional facilities as end-product users and can no longer be used for their intended purposes. Including materials recycled from the distribution chain. That is, materials that are recycled and reused after consumption by the consumers.

★Pre-consumer recycled materials:Materials transferred from the waste stream during the manufacturing process. Eliminate the reuse of certain materials, such as rework, regrind, or residual materials that are generated during processing and will be reused in the same processing process. That is, recycled materials that are not consumed by the consumers.

★Recycling ratio:The ratio of recycled materials in the product or packaging by mass. Only pre-consumer and post-consumer materials are considered recycled content.

In order to ensure that recycled materials are not replaced in the supply chain, every link in the supply chain should undergo GRS certification or participate in GRS audits. When an enterprise conducts GRS verification, the supplier must have a GRS certificate.

For example, if a weaving factory applies for a certificate, the yarn supplier must have a certificate;

If the garment factory applies for a certificate, the fabric supplier must have a certificate;

GRS certification is not required at the material collection stage, such as a company that collects bottles of waste products, or a company that sells the industrial waste such as leftovers.

The GRS standard is a product standard: the certification object is the product, and the product needs to meet the percentage of the weight of recycled materials to the total weight of the product ≥20%.

A:

Management system establishment → Submit verification request → Verification quotation → Payment → Audit → Improvement of audit deficiencies → Obtaining certification.★Verification unit:

Control Union(The Netherlands, Global)、CCPB(Italy)、ICEA(Italy)、ECOCERT(France)、NSF INTERNATIONAL(United States, Global)、ONECERT INTERNATIONAL(India)、USB(Turkey)、INTERTEK(China)、GCL INTERNATIONAL(global)、IDFL. Taiwan’s current verification units that can perform GRS verification are:Control Union Taiwan、IDFL、INTERTEK

★The raw material suppliers, manufacturers, and importers of any GRS applicable product category can apply for GRS verification. Its verification process includes:

- Submit GRS verification application

- Conduct document review: the scope and purpose of document review is to confirm that all documents have been correctly filled in and signed, the components of the product meet the requirements of the GRS standard, and all product materials and their suppliers meet the requirements of the GRS standard; after the documents are approved, the first on-site audit will be conducted.

-

The first on-site audit: The scope and purpose of the first on-site audit are to confirm:

- The content of recycled materials in the product meets the requirements of the GRS standard.

- The production process of the product does conform to the GRS standard.

- The industry should establish and maintain a documented logistics traceability system to accurately identify raw materials, semi-finished products and finished products.

- The industry should establish and maintain the records of the characteristics, quantities, sources, and destinations of all logistics.

- The industry should systematically control the status and quantity of all GRS-related raw materials and finished products.

- The industry should establish and maintain documented procedures to ensure compliance with the requirements of the GRS standard on environmental and social issues.

- Certificate issuance: Include the names of the companies and products that have passed the verification into the verified product database.

- Disagreement to the issuance of the certificate: If the issuance of the certificate is not agreed, the certification body will notify the applicant of the reason for the failure, the content of the non-compliance for the GRS standard, the priority and time limit of corrective and preventive measures, and the procedure for raising objections and deadlines. If the industry still wants to obtain the verification, it should submit documents before the deadline to prove that appropriate corrective and preventive measures have been taken. For cases for which corrective and preventive measures have been implemented, the certification body may re-arrange on-site inspections based on the severity of the non-conformity and the corrective & preventive status, or directly accept the improvement results and issue a certificate. If the industry fails to complete the improvement within 90 days, the GRS verification case will be automatically terminated.

- Carry out product labeling: products that have passed the verification should be labeled, and the labeling should include the blending rate of the product's recycled materials, the verification number, and the name of the certification body.

A:

RebornPlas is the pioneer in the recycled nylon industry.Through traceable product material and vertical integration production technology, we conduct comprehensive management regarding the quality of materials. In order to let the customers purchase traceable recycled nylon materials without worries, RebornPlas passed the Global Recycled Standard (GRS) verification in 2019. In addition to providing customers with proof of containing recycled content, it also fulfills the requirements of good corporate social responsibility, pollution prevention and treatment in the production process, and chemical restrictions.A:

GRS is the current internationally recognized standard for recycled materials. Many well-known international brands such as ADIDAS, 3M, PUMA, H&M, NIKE, etc. are all the members of this standard. Although GRS certification is currently mainly concentrated in the textile and garment industry, it is used to prove that its products or raw materials contain certain recycled materials. But now due to the widespread awareness of environmental protection and the advancement of recycling technology, it is not limited to a certain industry. Any recyclable materials like metal, ceramic and wood, as long as the product meets the entry threshold containing at least 20% recycled materials, is applicable. In other words, the standard can be used with any recycled input material and can be applied to any supply chain.Raw material manufacturers, processors, manufacturers, traders, warehouses, suppliers and brands who need to prove that their materials contain certain recycled content, and those who are willing to contribute to the earth, can apply for GRS certification.

A:

Without the GRS certification, the retailer/manufacturer could not use the GRS logo for any products labeling.

A:

You can go to the TE website below (GRC/GRS) to filter and search by country, or directly enter the name of the manufacturer to queryhttps://textileexchange.org/standards/find-a-certified-company/

A:

IDFL only has clear regulations on the use of GRS Logo, and there are no explicit regulations on the use of GRS certification codes. Therefore, the GRS certification code of RebornPlas can be disclosed or printed on the product package by the customer's downstream company.A:

- If you are a manufacturer, you only can prove that the purchased raw materials come from GRS certification;If you ask for relevant supporting documents from the seller (RebornPlas), you still can’t prove that the finished products made from your factory have passed GRS verification. Your manufacturing plant needs to apply for GRS verification.

- If you are a distributor, the principle is the same as above. Although there is no production line, the distributor can still apply for GRS system verification. The requirements for the distributor’s verification are simpler than those of manufacturers. The distributor only needs to implement the "document control".

A:

Like general ISO certification, GRS is verified once a year. The only difference is that GRS is a one-year certificate and is renewed every year, unlike ISO 9001, which is valid for 3 years.Cooperate with follow-up inspection and certificate renewal: GRS certificate is valid for 1 year each time. During the period, if the industry wants to withdraw from the verification, it should notify the certification body in writing 60 days in advance and pay the certificate fee within the validity period. The enterprises within the validity period of the certificate must cooperate with the certification body to conduct follow-up inspections to ensure continued compliance with GRS standards. Before the certificate expires, the certification body will re-evaluate the product and manufacturing process to decide whether to agree to renew the certificate. This evaluation mainly depends on the information obtained in the past 3 years.

A:

To obtain the GRS verification label (tag)as the following label, the product must contain at least 50% of the recycled content in its raw materials before it can use the GRS verification label (tag). The certification body or the final buyer planning to hang the GRS logo tag on the product need to pay the special attention for the GRS tag hanging.It’s also prohibited from changing the color of the logo label when the GRS logo is hung, and it must follow the regulations of the standard logo usage guidelines.

A:

The purpose of the GRS standard is to provide a standard that can verify the following items for the textile industry:- Product (finished product/intermediate product) recycling content standard;

- The degree of implementation of social responsibilities (human rights, basic welfare, anti-discrimination... etc.);

- Environmental protection;

- Chemical control;

- Reconcile the definitions of terms in the different application fields;

- Track and trace the input of recycled materials;

- Provide the customers (manufacturers or consumers) with a tool to make the wiser decisions;

- Reduce the harm to the human body and the environment caused by the production;

- Ensure that the materials in the final product are recyclable for re-using;

- Stimulate the innovation to solve the quality problems of using recycled materials

A:

Since the formulation and publication of the GRS standard in 2008, major international brands (such as ADIDAS, 3M, PUMA, H&M, NIKE, UA, Burberry, Gap...) have successively required the manufacturers involved in the supply chain to pass this certification standard. It is expected that there will be more and more industry partners will join the ranks of this certification standard.Environmentally friendly and sustainable are eternal topics; and recycling is an important way of sustainable production and consumption patterns. In recent years, the increase in global environmental awareness has become a development trend, and the mainstream brands have even more respected recyclable materials. It is understood that:

- Adidas announced the full use of recycled polyester fiber in 2024!

- Zara announced the full use of recycled and sustainable materials by 2025!

- H&M announced the full use of 100% recycled materials in 2030!

- Lidl announced that all plastic bottles under its own brand are 100% recyclable in 2025!

- IKEA promised to use only renewable or recycled materials in all products by 2030!

- Apple promised to end mining and its products will use 100% recycled materials!

A:

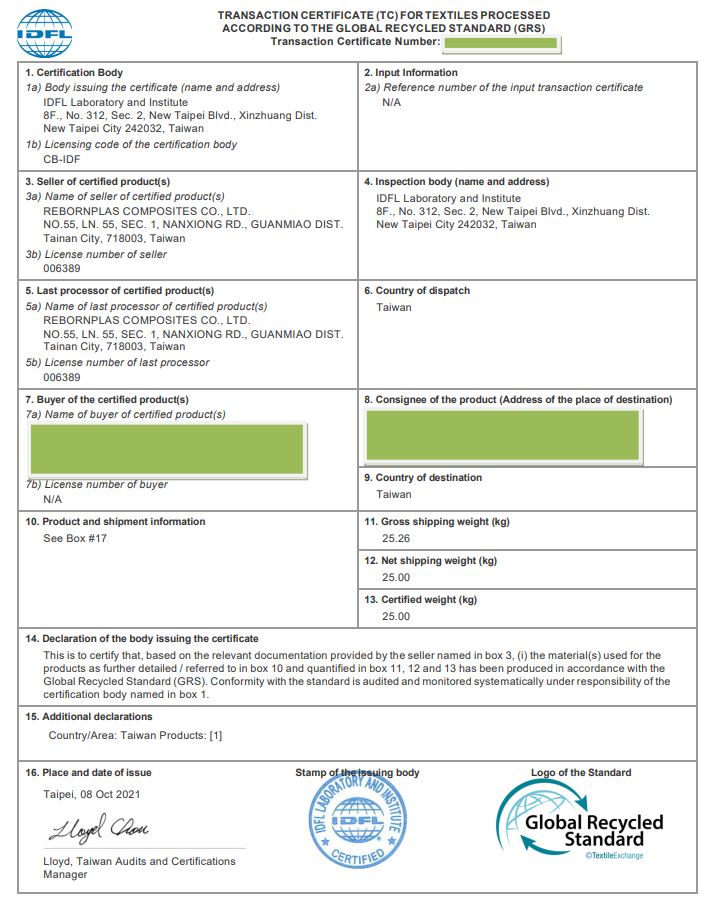

TC is an important document in the GRS certification process, just like the certificate of origin towards the materials and the birth certificate of the human being. TC is an indispensable part of the certification and operation process. TC is a key document in the recycling certification system to prove the reliability of its source. TC is similar to the concept of traceability of agricultural product resumes.★Transaction Certificate (TC):

- Standard proof certificate issued by the certification body.

- A guarantee letter confirming the percentage of recycled raw material content of the cargo shipped from a seller to a buyer.