PA6

Glass Fiber Reinforced/Impact Modified

Glass fiber reinforced nylon for enhanced strength, stiffness and low temperature impact resistance.

Our Glass fiber reinforced/ impact modified nylon is a type of nylon that has been reinforced with glass fibers. The enhanced toughness makes nylon more resistant to low temperatures and impact than glass fiber reinforced nylon.

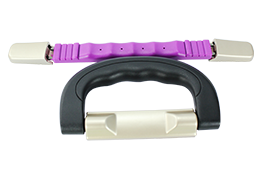

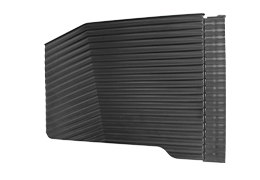

It can apply on different product production such as: bicycle parts, suitscase handle pulls, telescopic handle.

A5501GT15FDA2

Material:

Material:

PA6

Specification:

Specification:

Impact resistant 15% glass fiber reinforced

Color:

Color:

White, providing custom dyeing services

Certification:

Certification:

RoHS、REACH、GRS(Global Recycle Standard)

Package:

Package:

25kg

Property:

Property:

High stiffness and low temperature impact resistance

1. Materials Standard:

| Test Items Property | Test Method | Unit | Vaule |

|---|---|---|---|

| Mechanical Properties | |||

| Tensile Strength | ASTM D638 | Kg/cm2 | 800 |

| Elongation at Break | ASTM D638 | % | > 5 |

| Flexural Strength | ASTM D790 | kg/cm2 | 1200 |

| Flexural Modulus | ASTM D790 | kg/cm2 | 34700 |

|

IZOD Impact, Notched 1/8" 23°C IZOD Impact, Notched 1/8" -30°C |

ASTM D256 | kg-cm/cm | 18 |

|

Hardness Shore D Hardness Rockwell R Scale |

ASTM D2240 ASTM D785 |

- |

100 |

| Thermal | |||

|

Heat Deflection Temperature (18.6kg/cm2 ) |

ASTM D648 | °C | 170 |

| Other | |||

| Shrinkage | ASTM D955 | % | 0.3~1.0 |

| Melt Index | ASTM D1238 | g/10min | - |

| Specific Gravity | ASTM D792 | - | 1.21 |

| Ash Content | ASTM D482 | % | 15 |

| Equilibrium Moisture Content | ASTM D570 | % | < 0.3 |

| Flammability | UL 94 | 1.6mm | - |

2. Molding Condition:

| Drying | Melt Temp | Inject Press. |

|---|---|---|

| 80~100°C*4HR | 235~260°C | 20kg/cm2 |

Note: Test Conditions: 23℃, 50%RH, 24 hours. The datasheet is for your reference. And the data above will vary as the actual use condition changes.

A3801GT10BKF2

Material:

Material:

PA6

Specification:

Specification:

Impact resistant 10% glass fiber reinforced

Color:

Color:

Black

Certification:

Certification:

RoHS、REACH、GRS(Global Recycle Standard)

Package:

Package:

25kg

Property:

Property:

High stiffness and low temperature impact resistance

1. Materials Standard:

| Test Items Property | Test Method | Unit | Vaule |

|---|---|---|---|

| Mechanical Properties | |||

| Tensile Strength | ASTM D638 | Kg/cm2 | 550 |

| Elongation at Break | ASTM D638 | % | < 20 |

| Flexural Strength | ASTM D790 | kg/cm2 | 1000 |

| Flexural Modulus | ASTM D790 | kg/cm2 | 28000 |

|

IZOD Impact, Notched 1/8" 23°C IZOD Impact, Notched 1/8" -30°C |

ASTM D256 | kg-cm/cm |

20 |

|

Hardness Shore D Hardness Rockwell R Scale |

ASTM D2240 ASTM D785 |

- |

100 |

| Thermal | |||

|

Heat Deflection Temperature (18.6kg/cm2 ) |

ASTM D648 | °C | 170 |

| Other | |||

| Shrinkage | ASTM D955 | % | 0.3~1.0 |

| Melt Index | ASTM D1238 | g/10min | - |

| Specific Gravity | ASTM D792 | - | 1.15 |

| Ash Content | ASTM D482 | % | 10 |

| Equilibrium Moisture Content | ASTM D570 | % | < 0.3 |

| Flammability | UL 94 | 1.6mm | - |

2. Molding Condition:

| Drying | Melt Temp | Inject Press. |

|---|---|---|

| 80~100°C*4HR | 235~260°C | 20kg/cm2 |

Note: Test Conditions: 23℃, 50%RH, 24 hours. The datasheet is for your reference. And the data above will vary as the actual use condition changes.

A3501GT15BKA2

Material:

Material:

PA6

Specification:

Specification:

Impact resistant 15% glass fiber reinforced

Color:

Color:

Black

Certification:

Certification:

RoHS、REACH、GRS(Global Recycle Standard)

Package:

Package:

25kg

Property:

Property:

High stiffness and low temperature impact resistance

1. Materials Standard:

| Test Items Property | Test Method | Unit | Vaule |

|---|---|---|---|

| Mechanical Properties | |||

| Tensile Strength | ASTM D638 | Kg/cm2 | 730 |

| Elongation at Break | ASTM D638 | % | < 5 |

| Flexural Strength | ASTM D790 | kg/cm2 | 1200 |

| Flexural Modulus | ASTM D790 | kg/cm2 | 34000 |

|

IZOD Impact, Notched 1/8" 23°C IZOD Impact, Notched 1/8" -30°C |

ASTM D256 | kg-cm/cm |

14 |

|

Hardness Shore D Hardness Rockwell R Scale |

ASTM D2240 ASTM D785 |

- |

100 |

| Thermal | |||

|

Heat Deflection Temperature (18.6kg/cm2 ) |

ASTM D648 | °C | 170 |

| Other | |||

| Shrinkage | ASTM D955 | % | 0.3~1.0 |

| Melt Index | ASTM D1238 | g/10min | - |

| Specific Gravity | ASTM D792 | - | 1.20 |

| Ash Content | ASTM D482 | % | 15 |

| Equilibrium Moisture Content | ASTM D570 | % | < 0.3 |

| Flammability | UL 94 | 1.6mm | - |

2. Molding Condition:

| Drying | Melt Temp | Inject Press. |

|---|---|---|

| 80~100°C*4HR | 235~260°C | 20kg/cm2 |

Note: Test Conditions: 23℃, 50%RH, 24 hours. The datasheet is for your reference. And the data above will vary as the actual use condition changes.

A3000GT30BKC1

Material:

Material:

PA6

Specification:

Specification:

Impact resistant 30% glass fiber reinforced

Color:

Color:

Black

Certification:

Certification:

RoHS、REACH、GRS(Global Recycle Standard)

Package:

Package:

25kg

Property:

Property:

Ultra toughness, low temperature impact resistance and high stiffness

1. Materials Standard:

| Test Items Property | Test Method | Unit | Vaule |

|---|---|---|---|

| Mechanical Properties | |||

| Tensile Strength | ASTM D638 | Kg/cm2 | 1250 |

| Elongation at Break | ASTM D638 | % | < 5 |

| Flexural Strength | ASTM D790 | kg/cm2 | 2000 |

| Flexural Modulus | ASTM D790 | kg/cm2 | 70000 |

|

IZOD Impact, Notched 1/8" 23°C IZOD Impact, Notched 1/8" -30°C |

ASTM D256 | kg-cm/cm |

15 |

|

Hardness Shore D Hardness Rockwell R Scale |

ASTM D2240 ASTM D785 |

- |

115 |

| Thermal | |||

|

Heat Deflection Temperature (18.6kg/cm2 ) |

ASTM D648 | °C | 190 |

| Other | |||

| Shrinkage | ASTM D955 | % | 0.3~0.8 |

| Melt Index | ASTM D1238 | g/10min | - |

| Specific Gravity | ASTM D792 | - | 1.34 |

| Ash Content | ASTM D482 | % | 30 |

| Equilibrium Moisture Content | ASTM D570 | % | < 0.3 |

| Flammability | UL 94 | 1.6mm | - |

2. Molding Condition:

| Drying | Melt Temp | Inject Press. |

|---|---|---|

| 80~100°C*4HR | 235~260°C | 20kg/cm2 |

Note: Test Conditions: 23℃, 50%RH, 24 hours. The datasheet is for your reference. And the data above will vary as the actual use condition changes.

A3000GT35BKH1

Material:

Material:

PA6

Specification:

Specification:

Impact resistant 35% glass fiber reinforced

Color:

Color:

Black

Certification:

Certification:

RoHS、REACH、GRS(Global Recycle Standard)

Package:

Package:

25kg

Property:

Property:

Low temperature impact resistance and high stiffness

1. Materials Standard:

| Test Items Property | Test Method | Unit | Vaule |

|---|---|---|---|

| Mechanical Properties | |||

| Tensile Strength | ASTM D638 | Kg/cm2 | 1350 |

| Elongation at Break | ASTM D638 | % | < 5 |

| Flexural Strength | ASTM D790 | kg/cm2 | 2200 |

| Flexural Modulus | ASTM D790 | kg/cm2 | 75000 |

|

IZOD Impact, Notched 1/8" 23°C IZOD Impact, Notched 1/8" -30°C |

ASTM D256 | kg-cm/cm |

15 |

|

Hardness Shore D Hardness Rockwell R Scale |

ASTM D2240 ASTM D785 |

- |

115 |

| Thermal | |||

|

Heat Deflection Temperature (18.6kg/cm2 ) |

ASTM D648 | °C | 190 |

| Other | |||

| Shrinkage | ASTM D955 | % | 0.3~0.8 |

| Melt Index | ASTM D1238 | g/10min | - |

| Specific Gravity | ASTM D792 | - | 1.38 |

| Ash Content | ASTM D482 | % | 35 |

| Equilibrium Moisture Content | ASTM D570 | % | < 0.3 |

| Flammability | UL 94 | 1.6mm | - |

2. Molding Condition:

| Drying | Melt Temp | Inject Press. |

|---|---|---|

| 80~100°C*4HR | 235~260°C | 20kg/cm2 |

Note: Test Conditions: 23℃, 50%RH, 24 hours. The datasheet is for your reference. And the data above will vary as the actual use condition changes.

A3000GT45BKC1

Material:

Material:

PA6

Specification:

Specification:

Impact resistant 45% glass fiber reinforced

Color:

Color:

Black

Certification:

Certification:

RoHS、REACH、GRS(Global Recycle Standard)

Package:

Package:

25kg

Property:

Property:

Low temperature impact resistance and high stiffness

1. Materials Standard:

| Test Items Property | Test Method | Unit | Vaule |

|---|---|---|---|

| Mechanical Properties | |||

| Tensile Strength | ASTM D638 | Kg/cm2 | 1550 |

| Elongation at Break | ASTM D638 | % | < 5 |

| Flexural Strength | ASTM D790 | kg/cm2 | 2600 |

| Flexural Modulus | ASTM D790 | kg/cm2 | 80000 |

|

IZOD Impact, Notched 1/8" 23°C IZOD Impact, Notched 1/8" -30°C |

ASTM D256 | kg-cm/cm |

18 |

|

Hardness Shore D Hardness Rockwell R Scale |

ASTM D2240 ASTM D785 |

- |

115 |

| Thermal | |||

|

Heat Deflection Temperature (18.6kg/cm2 ) |

ASTM D648 | °C | 190 |

| Other | |||

| Shrinkage | ASTM D955 | % | 0.3~0.8 |

| Melt Index | ASTM D1238 | g/10min | - |

| Specific Gravity | ASTM D792 | - | 1.48 |

| Ash Content | ASTM D482 | % | 45 |

| Equilibrium Moisture Content | ASTM D570 | % | < 0.3 |

| Flammability | UL 94 | 1.6mm | - |

2. Molding Condition:

| Drying | Melt Temp | Inject Press. |

|---|---|---|

| 80~100°C*4HR | 235~260°C | 20kg/cm2 |

Note: Test Conditions: 23℃, 50%RH, 24 hours. The datasheet is for your reference. And the data above will vary as the actual use condition changes.