As a leading manufacturer of NylonPA6 and PA66 , we leverage our expertise and state-of-the-art facilities to deliver top-quality products. Clients often ask how to determine the best choice between Nylon PA6 and PA66 for their specific applications. In this blog, we'll provide a detailed comparison, highlighting their unique properties to help you make an informed decision.

What is Nylon PA6 and PA66?

Both Nylon PA6 and PA66 are members of the advanced polyamide family and have been widely used in various applications due to their excellent mechanical properties, heat resistance, and chemical resistance. While they share some similarities, their slight differences in molecular structure give rise to unique properties that can influence your material selection.

Nylon PA6 : An Overview

Nylon PA6 is a semi-crystalline material, made from polymerization of caprolactam monomers. It is known for its versatility, strength, and adaptability, providing remarkable wear and chemical resistance. This makes Nylon PA6 an excellent choice for applications that demand high mechanical strength and resistance to harsh environments, such as automotive components and heavy-duty consumer goods.

Nylon PA66 : A closer look

Nylon PA66, often considered Nylon 6’s sibling, is made from the polymerization of hexamethylene diamine and adipic acid, resulting in a material that is slightly more crystalline and rigid. Nylon PA66 offers improved mechanical properties, heat resistance, and dimensional stability when compared to Nylon PA6. Its inherent strength, stiffness, and ability to maintain performance at higher temperatures make it a suitable choice for applications that involve high loads and sustained heat exposure.

Deciphering the Key Differences : Nylon PA6 vs PA66

Mechanical properties

While Nylon PA6 boasts impressive mechanical strength and resistance to harsh environments, Nylon PA66 edges out in terms of higher tensile strength, stiffness, and heat resistance. Nylon PA66's performance is particularly noteworthy when subjected to high loads and sustained exposure to high temperatures. This makes PA66 more suited for applications that involve demanding mechanical loads and consistent heat presence.

Moisture absorption

Nylon PA6 and PA66 exhibit similar moisture absorption levels. However, Nylon PA6 tends to swell more when submerged in water. In scenarios where tensile strength and stiffness at higher humidity levels are crucial, Nylon PA66 would be the better choice due to its lower water absorption rate and better dimensional stability.

Processing

Nylon PA6 is slightly easier to process due to its lower melting temperature when compared to Nylon PA66. This means that PA6 can be more effectively molded, extruded, or cast, offering some benefits concerning production efficiency. Moreover, Nylon PA6 also exhibits a lower tendency to warp as compared to PA66, providing an edge in applications that demand complex or intricate shapes.

A Comparative Snapshot of Key Properties

Here's a comparison table highlighting their key properties:

|

Property |

Nylon PA6 |

Nylon PA66 |

|

Mechanical Strength |

High |

Very High |

|

Stiffness |

High |

Very High |

|

Heat Resistance |

Moderate to High |

High |

|

Chemical Resistance |

High |

High |

|

Wear Resistance |

High |

High |

|

Moisture Absorption |

Moderate |

Moderate to Low |

|

Dimensional Stability |

Moderate to High |

High |

|

Processing Ease |

Good |

Moderate |

|

Melting Temperature |

Lower |

Higher |

|

Performance in Humidity |

Moderate |

High |

Please note that this comparison table provides a general idea of differences between Nylon PA6 and PA66. The specific grades and formulations of each nylon may have varying properties, depending on the manufacturer and additives used. As a Nylon expert and manufacturer, our team is ready to help you make an informed decision based on your specific project requirements, ensuring the best-suited Nylon grade for your application.

Application Domains of Nylon PA6 and Nylon PA66

Choosing between Nylon PA6 and Nylon PA66 heavily relies on their application domains. Nylon PA6, owing to its strength, adaptability, and excellent chemical resistance, is widely chosen for automotive components such as rear view mirror base, headlight base, rearview mirror rotation axes, fender, dashboards, radiator tanks, and wheel covers. It's also popular in consumer goods that require high mechanical strength and weather endurance, like office chairs, suitcase, baby strollers, sporting goods and electrical and pneumatic hand tools.

On the other hand, Nylon PA66's improved mechanical properties, heat resistance, and dimensional stability are best utilized in demanding applications. This includes under-hood automotive components, cable ties, gears, radiator tanks , and bushings that require consistent high performance in challenging environments.

It's worth noting that both materials find use across several industries, including automotive, electronics, machinery, and consumer goods. Regardless of the chosen material, we, as nylon experts, are committed to crafting bespoke solutions tailored to your specific requirements, leveraging the strength of both Nylon PA6 and PA66.

Choosing Between Nylon PA6, PA66, or Recycled Nylon for Your Application

When deciding between Nylon PA6, PA66, or our recycled Nylon for your application, it is essential to carefully consider the specific requirements and operating conditions your product will be exposed to. Nylon PA6, with its remarkable wear resistance, adaptability, processing efficiency ,and lower cost, is a versatile choice for a broad range of applications. On the other hand, Nylon PA66 offers higher mechanical strength, heat resistance, and dimensional stability in humidity, making it a standout choice for high-performance applications in demanding environments.

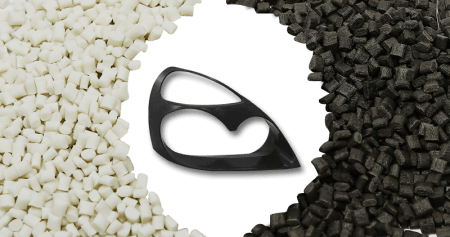

In response to the pressing need for environmental sustainability, we also manufacture recycled Nylon made from discarded fishing nets, scrap Yarn and abandoned airbags, an eco-friendly alternative featuring properties on par with virgin Nylon PA6 and PA66.

For more in-depth information about our recycled Nylon and how to select it for your needs, be sure to check out our blog post, How to Select Recycled Nylon Made by Ocean Plastic Net – 4 Considerations. This comprehensive guide will provide you with all the vital points to consider while opting for this sustainable alternative, contributing not only to your product's performance but also to environmental conservation.

As a trusted Nylon expert and manufacturer, we are committed to helping you make the best material choice for your project. Our team of experienced engineers is always on hand to assist in selecting the best-suited Nylon grade, be it virgin or recycled, and developing tailor-made solutions to meet your specific needs.Contact us today to discuss your application requirements.